One-Step Structure Control of Cellulose Nanofibers Using Electrophoretic Deposition

January 6, 2023

Background / Context / Abstract:

Cellulose nanofibers (CNFs) are wood-derived high-performance nanofibers with a width of about 3 to 15 nm that possess excellent properties. They are lightweight and offer high strength, high heat resistance, high specific surface area, biodegradability, biocompatibility, and sustainability. In recent years, several companies, including Japanese companies, have begun to put CNF products on the markets, and in many cases, they are available in the form of CNF/water dispersion. However, there are many challenges in using CNFs. In particular, when CNFs are used to form a film, hydrogel, aerogel, or other structures, various considerations and procedures are needed due to the unique properties of CNFs in each process such as dehydration, fixation (cross-linking) of CNFs, orientation control, and forming.

Technology Overview:

A feature of this technology is that cellulose nanofibers can be fixed in any orientation and any shape using simple equipment and procedure (Fig. 1). This technology uses dilute CNF/water dispersion as a starting material. The only necessary devices are a pair of electrodes (anode and cathode) and a DC power supply. Just inserting the anode and cathode into a CNF/water dispersion and applying a DC voltage of about 1 to 40 V causes the CNFs, which are negatively charged due to electrophoretic deposition, to be deposited around the anode and fixed. At this time, the oriented state changes from a horizontal orientation to a vertical orientation according to the applied voltage. Even if the electrode shape is a pattern shape or a three-dimensional shape, the CNFs are fixed to the electrode in an arbitrary thickness and oriented state. This means that, by using this technology, it is possible to fix CNFs in any oriented state and shape in one step.

Benefits:

Compared with conventional technologies, this technology has the advantages of simplicity and greater flexibility. In general, when creating an oriented CNF hydrogel such as one realized by this technology, four steps are needed: density adjustment (condensation) of CNF/water dispersion, orientation control, fixation, and postforming. However, with this technology, concentration, orientation, fixation, and forming are completed through only voltage application. Because of the simple procedure, this technology has greater flexibility in application than conventional orientation control methods, and therefore there are many areas in which this technology has potential.

Potential Applications / Potential Markets:

Major application examples include patterning, bio-mimetics, and CNF film three-dimensional forming. There are various areas in which this technology can be used, including the development of functionalized materials (functionally graded materials, insulation, shock absorbing materials, etc.), the development of sustainable alternative materials (alternatives to plastic, biodegradable materials, etc.), the medical field (biomedical gel electrodes, artificial joints, cell culture, etc.), the catalyst field (microchannels, flow reactors, etc.), and the rechargeable battery field (electrode surface treatment, separators, etc.).

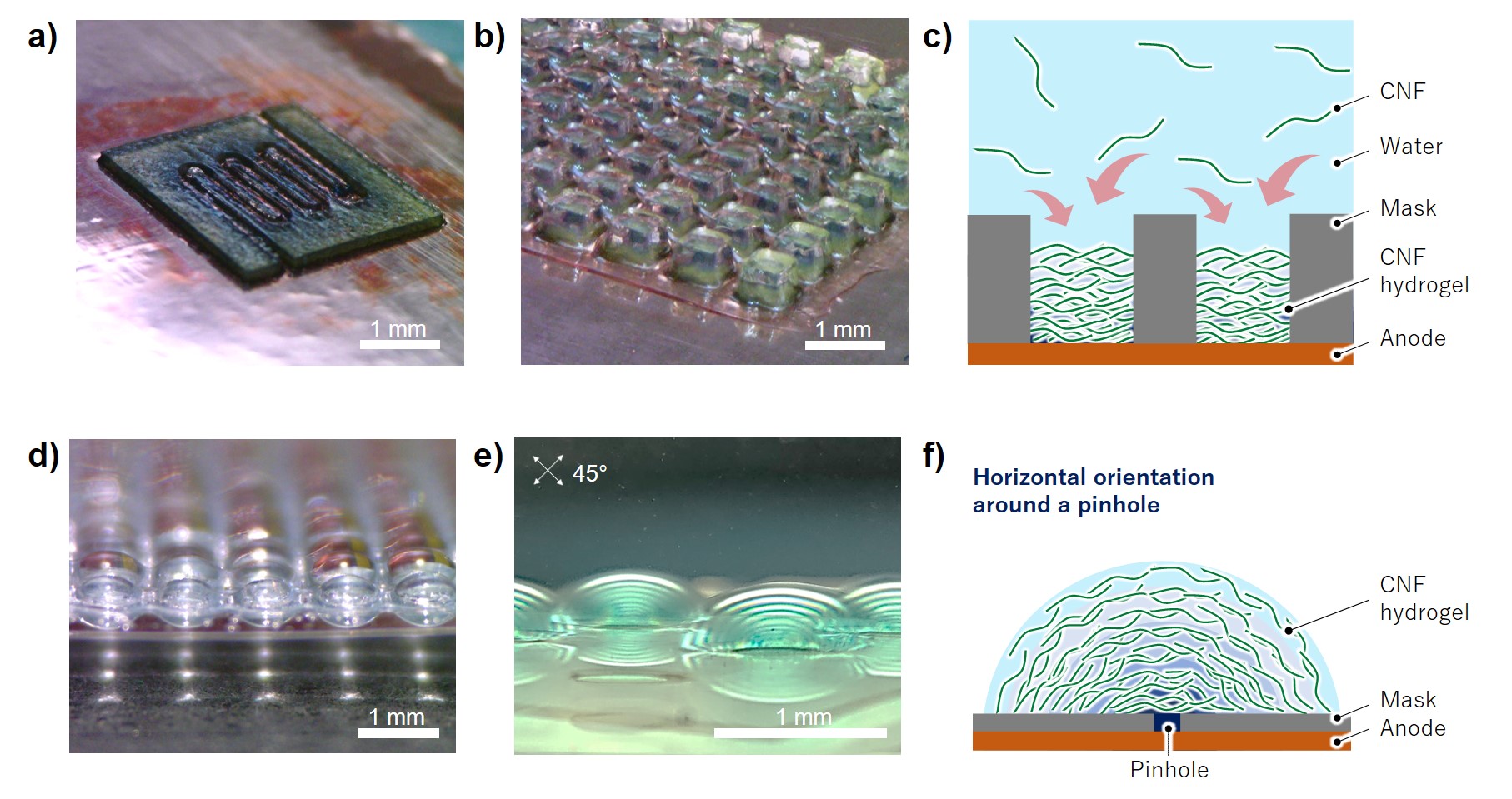

Patterning: Placing a mask on the electrode or using an electrode formed by patterning can fix CNFs in any pattern shape (Fig. 2). Of course, it is possible to combine patterning and orientation control. For example, it is easy to produce microchannels, and hydrogel pillar arrays, lens arrays, and the like for gel electrodes.

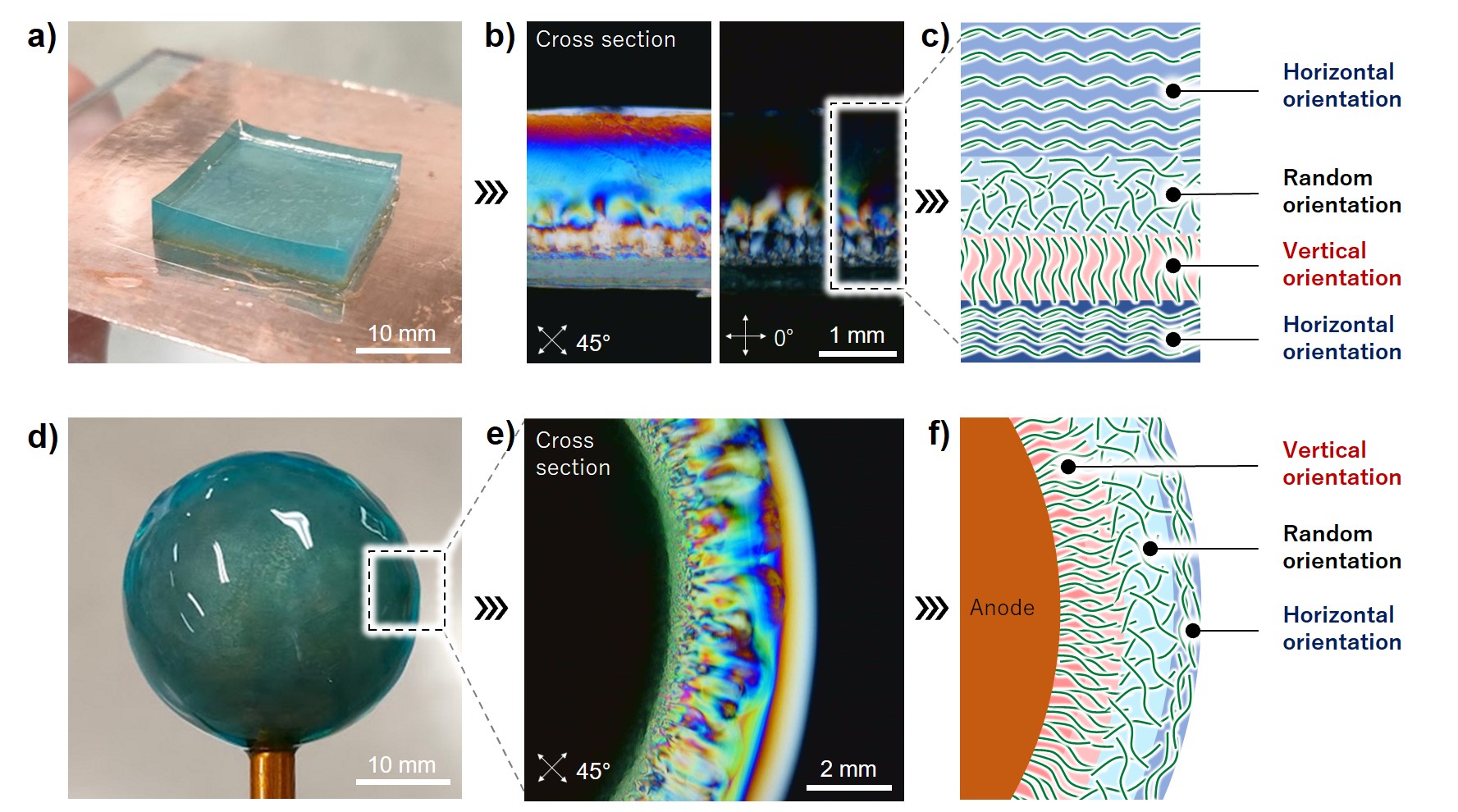

Biomimetics: It is possible to build up nanofibers in vertical, random, and horizontal orientations in any thickness. The only necessary operation is to change the applied voltage during deposition. For example, complex hierarchical structures such as cartilage tissues can be produced (Fig. 3). This technology is expected to be applied to the medical field and the biological field as well.

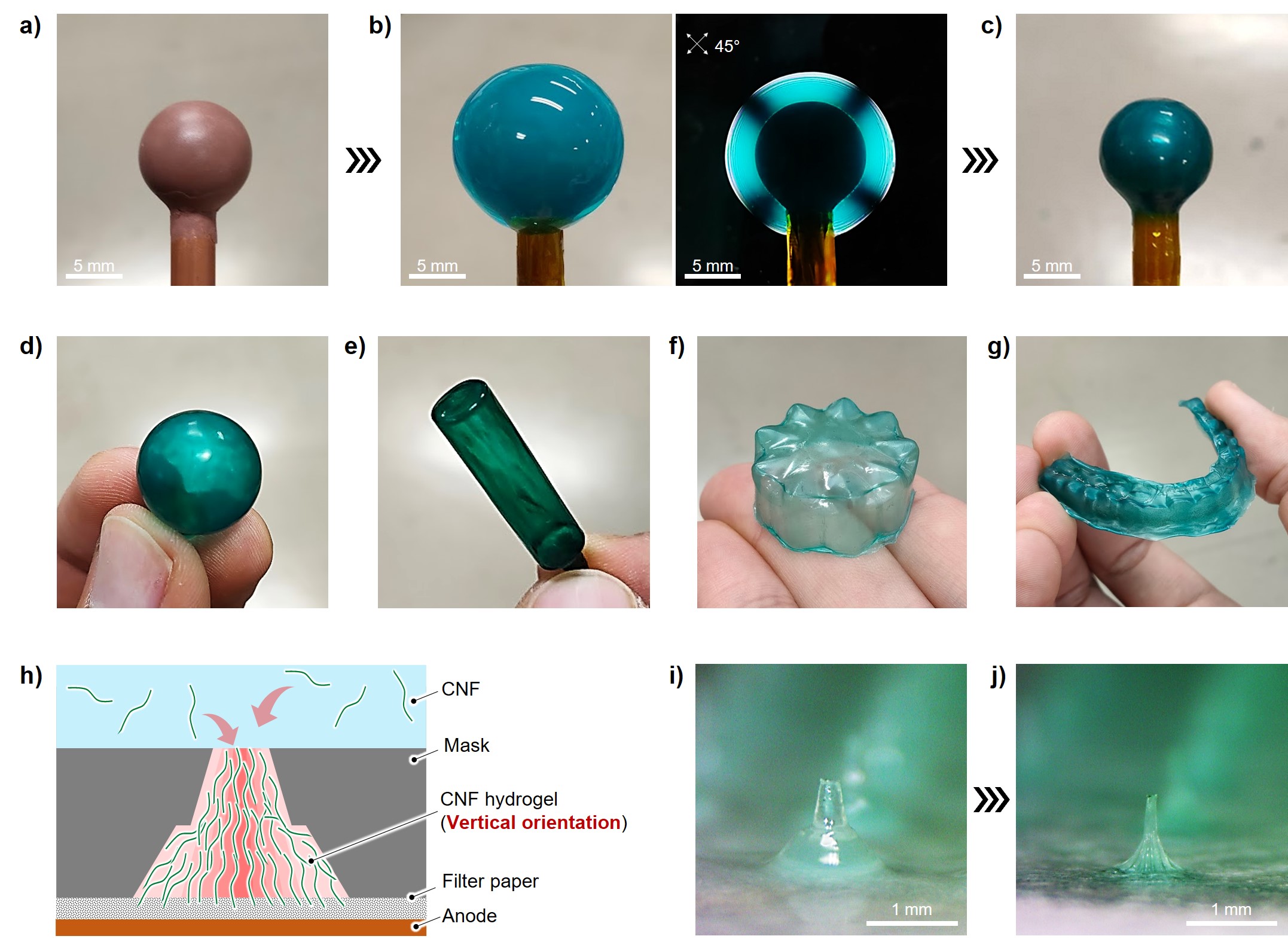

CNF film three-dimensional forming: In a CNF hydrogel produced using this method, the CNFs are oriented in the whole gel. Therefore, reflecting the oriented state, they are anisotropically shrunk during drying. That is, horizontally oriented CNF hydrogel is dried in a film shape adhered to the electrode, and vertically oriented CNF hydrogel is dried in a rod shape perpendicular to the electrode. By utilizing this feature, it is possible to produce, for example, a three-dimensionally formed CNF film tailored to the electrode shape (Fig. 4). Or all-CNF microneedle arrays can be produced by combining patterning and vertical orientation

State of Development / Opportunity / Seeking:

・Available for exclusive and non-exclusive licensing

・Exclusive/non-exclusive evaluation for defined period (set up for options)

・Collaborative/supportive research

※Seeking

1. Development partner

2. Licensing

IP Status:

PCT applied in Japanese

Figures:

Fig. 1 a): The basic structure of the device used for structural control in this invention and the image of nanofibers that deposit on the anode. Appearances and cross sections of nanofiber hydrogel fixed on the anode in b) horizontal orientation, c) random orientation, and d) vertical orientation.

Fig. 2: Examples of application to patterning. You can produce microstructures such as a) microchannels and c) hydrogel pillar arrays just by placing a mask on the electrode and applying a voltage. By combining a mask and orientation control, you can also produce structures such as lens arrays of d), e) and f).

Fig. 3 a): By making nanofibers deposit while changing the applied voltage, you can build up the nanofibers in different orientations. b): As the electrode shape is not restricted, for example, by building up nanofibers on a spherical anode in the order of vertical orientation, random orientation, and horizontal orientation, you can reproduce complex biological tissues such as cartilage tissues.

Fig. 4: For example, a) you prepare a spherical anode, and b) fix nanofibers to its surface in a horizontal orientation to form nanofiber hydrogel. c) The horizontally oriented nanofiber hydrogel is hard to crack even when it is dried because its shrinkage in the horizontal direction is suppressed, and d) by removing the anode after drying, you can obtain a film formed along the three-dimensional shape. If you use an anode in a different shape, you can produce e) a cylindrical shape, f) a complex shape, and g) a mouthpiece-like shape. h) By combining patterning with a mask and vertical orientation, i) and j) you can also obtain needle-shaped articles such as a microneedle after drying.

Contact:

![]()